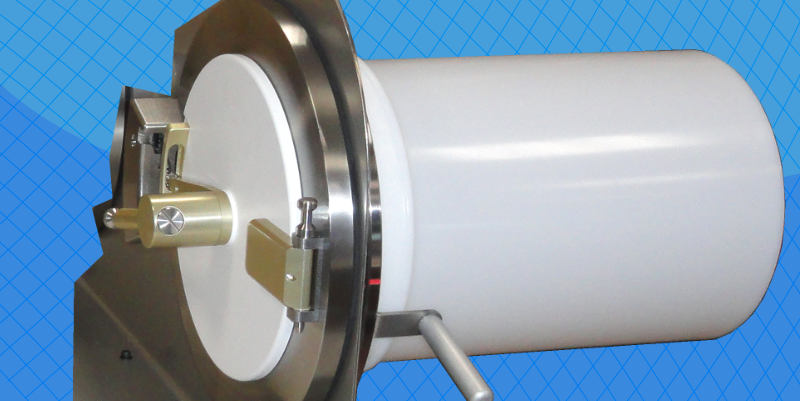

Cape Europe - Rapid Transfer Ports (RTPs)

The The OptimaTS rapid transfer system is a patented design. The OptimaTS design takes rapid transfer technology to a new level of performance. The Cape rapid transfer system is fully compatible with the La Calhène DPTE range of alpha and beta flanges including the injection moulded consumable flange.

The OptimaTS alpha ports have the same fixing diameters as DPTE alpha ports.

The OptimaTS security mechanism is fully interlocked with the following automatic functions:

- The alpha port cannot be opened without a beta part connected.

- The alpha port cannot be opened if a beta flange is docked without the beta door.

- The beta cannot be detached from the alpha door whilst the alpha door is open.

- The alpha and beta doors are mechanically locked together when the beta is connected and the alpha door open.

- It is impossible to “cheat” the interlocks from the outside of the enclosure.

- Improved reliability of mechanical interlocks by the use of rotating parts only.

- No parts moving parallel to the axis of the alpha flange so no fragile membranes are used for sealing the security mechanism.

- Standardised design. The OptimaTS security mechanism is standard for all the Cape ports with the use of the same parts on different diameters.

- Ergonomic design of Alpha door handle for easily operation when wearing neoprene or hypalon gloves.

- Careful choice of materials for all components for minimum weight and optimum mechanical reliability.

The innovative design of the security actuating mechanism ensures that no damage to the beta flange or door occurs during the connection. The interlock system acts directly on the main-shaft of the security mechanism to ensure a positive, precise and reliable action.

No fragile membranes are used for sealing the security mechanism. The use of o-ring seals only guarantees robustness and long term reliability of leak tightness.

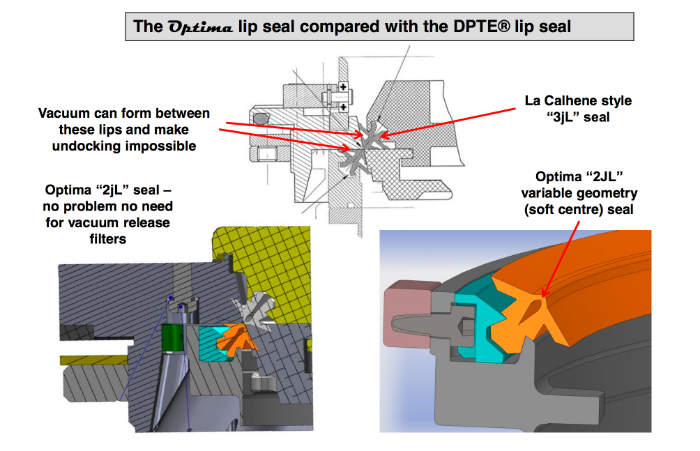

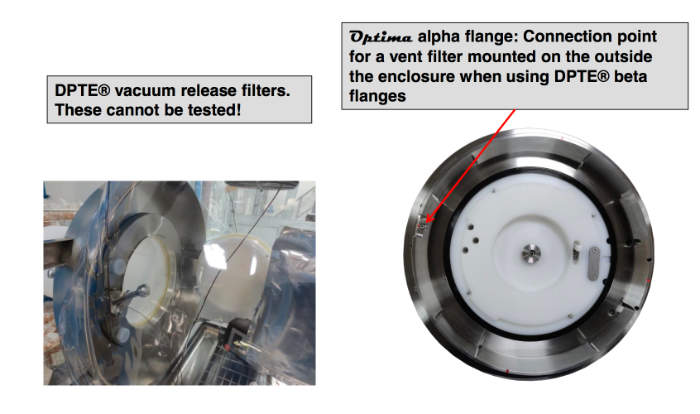

The OptimaTS system includes new high performance lip seals with lower torque and reduced zone of incertitude.

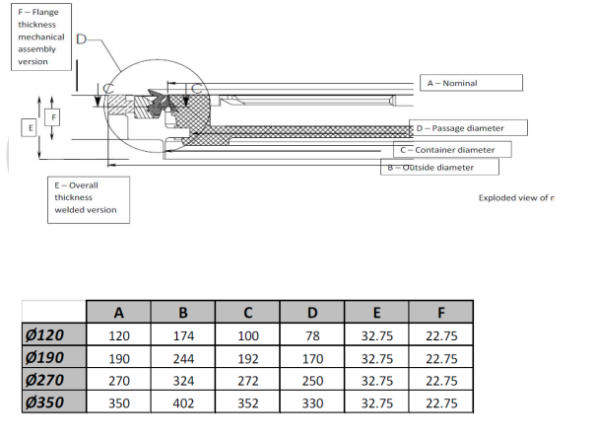

Specification

1. Leak tightness: 50pa/min for a test pressure of 3800Pa (270 diameter beta flange). 190 alpha SSPE flange better than 1.6 pa/min at 1000 Pa

2. Surface finish: Better than 0.6 Ra (1.6μm copmliant to ISO 1302).

3. Regulatory compliance:

Conforms with cGMP regulatory requirements for transfer devices.

Guaranteed zero contamination when used for transfers between a Grade A aseptic processing environments in a grade D background.

Suitable for use in a non-classified environment.

Suitable for use on BSL3 enclosures.

4. Range of normal operating conditions:

Temperature +16 ̊C to +30 ̊C

Normal operating pressure range +/- 500Pa. Maximum permissible pressure = + 3800Pa RH 10 to 80% @ 25 ̊C

5. Autoclaving: 131 ̊C at 30 mbars max.

Features and Benefits

Optima - Performance

- Leak tightness performance equals competition.

- TAMPER PROOF Interlocks:

- Alpha cannot be opened without beta

- Beta cannot be removed when alpha is open

- Cannot dock and open with a beta without beta door

- Safety button on door handle.

- Improved control of “ring of concern” with new seal design.

- Good ergonomics for ease of use:

Low docking torque

Handle can be placed in 4 different positions. - Fully interchangeable parts.

- Major parts can be changed without dismantling alpha flange.

- All beta flanges have wear limit indicators

Advantages of Optima RTP

Alpha

Direct acting interlocks. The beta flange acts directly on the main-shaft of the security mechanism to ensure a positive, precise and reliable action.

No fragile membranes on moving parts Use of O-ring seals only to guarantee long term reliability of leak tightness.

No damage to the beta parts. The innovative design of the security actuating mechanism in the alpha port ensures that no damage to the beta door occurs during the connection.

Ergonomic design The handle can be positioned either horizontally or vertically

Reduction of the ring of potential contamination with new lip seal design.

Reduced docking torque from new design of locking ramps

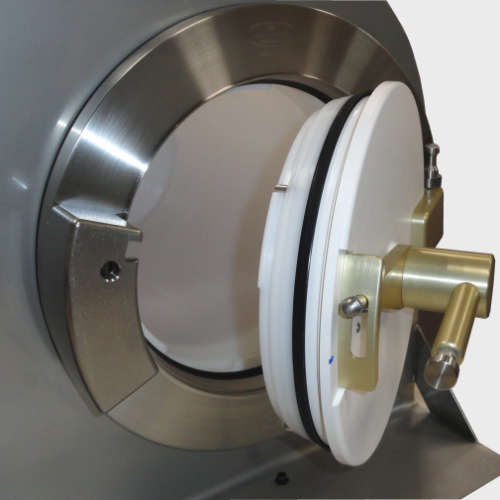

Easy to clean, smooth, high quality finish. Finishes conform to ISO 1302 and smooth accessible surfaces for good cleanability. Crevasse free design, suitable for use in aseptic environments. Drain holes to prevent retention of cleaning fluids.

Design suitable for surface bio-decontamination processes such as vaporised hydrogen peroxide

Bio-decontamination compatible materials for all components. Our ports are compatible with VHP, Chlorine dioxide, Formaldehyde etc. and non- oxidising cleaning agents such as Trigene and acid based oxidising disinfection products such as Virkon

Maintainability. Security mechanism, hinge and alpha door designed for easy maintenance and replacement without the need to dismantle the flange from the isolator. Security mechanism, hinge and alpha door design common to all port sizes

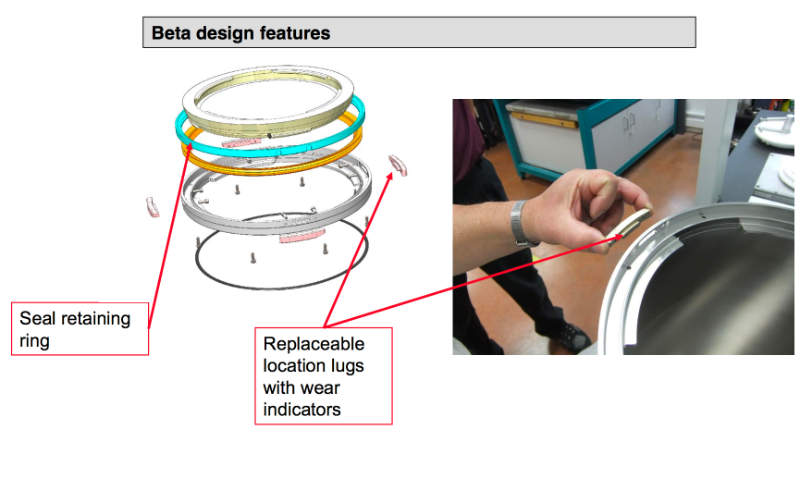

Beta

Optimal positioning of the lip seal, held in place by a securing ring which is either clipped (PE containers) or bolted to the flange (stainless steel containers) depending on the flange material.

Replaceable locating lugs on the stainless steel and Aluminium flanges robust design made from low friction materials

Wear indicators on locating lugs of all flanges. The locating lugs on the stainless steel and aluminium flanges are replaceable making it easy for the user to restore the beat flange to ex-works condition at any time.

Easy to change lip seal

Reduction of the ring of potential contamination with new lip seal design.

Reduced docking torque from new design of locking ramps

Reduced docking torque by the use of a low friction surface finish on the lip seals.